|

For the Analyst:

The term analyst often conjures images of bookish people, wearing coke-bottle

glasses, wielding very sharp pencils to calculate the most obscure statistics.

While this image is widely held, it distracts us from recognizing the purest,

most practical, and easiest form of analysis: Graphical Analysis.

The term analyst often conjures images of bookish people, wearing coke-bottle

glasses, wielding very sharp pencils to calculate the most obscure statistics.

While this image is widely held, it distracts us from recognizing the purest,

most practical, and easiest form of analysis: Graphical Analysis.

The human brain is a powerful graphical engine, and quickly recognizes patterns in images.

The brain can instantly recognize important facts about visual data without calculating anything.

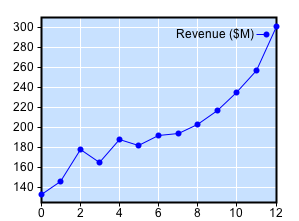

When data are presented graphically, for example in a run chart, one can very quickly

identify trends; a rising or falling trend, a steady condition without change, or disorganized

data with lots of variation.

Everyone can be an analyst, and LiveSPC.com provides an easy way to build

Your Enterprise Visual Workplace™ with simple, yet powerful, graphical representations

of your enterprise data. Your brain does the rest! No messy calculations, no complicated

analytical software... just your data, in picture form, ready to digest.

So you, the Analyst, have a couple of questions to answer:

- What data should I measure and collect?, and

- How should I represent the data?

Enterprise Data

Results are King in any enterprise, so they should be measured:

- Revenue

- Order Fulfillment Time

- On-Time Performance

- Backorder Value

- Product Quality

- Customer Satisfaction

- Project Earned Value

What you count as results in your business is unique and varied, but always reflects

some output of the business. Business financials are a natural here, but those measures of

performance valued by your Customers are also very important, like order fulfillment times and other

product quality measurements. You may even want to brag about these results by embedding LiveSPC

workspaces on your own website.

For companies involved in larger development projects, or built-to-order products, it may be useful

to measure and communicate project performance metrics like earned value, bug counts, or problem reports.

These represent work completed or accrued work backlog.

Companies managing operations benefit from monitoring the inputs to their operations,

or resources required for production, like:

- Server Availability

- Active Website Sessions

- Registered Users

- Network Performance

- Key Materials Inventory

Inputs are anything your enterprise requires to operate effectively and efficiently.

Anything critical to your operation, those things you cannot function without, should be measured.

Once you have a wish-list of data you'd like to collect visit your IT or Systems department to

arrange to have them configure a live feed of your data to LiveSPC.com.

Data Representations

Once you've got your data fed to datasets on LiveSPC you can construct reports that display

that data in a form that best suits your need. The following table describes the available

graphical representations for your data, when to apply them, and what analyses they enable.

|

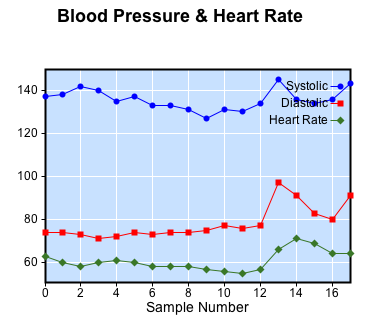

Run Chart

The Run chart is a basic depiction of a sequence of measured samples. This form enables

the identification of trends, increasing, decreasing, steady, or disorganized progress.

|

|

|

Multiple numerical samples can be plotted from the same dataset. Each column in the dataset

will be drawn and labeled separately.

|

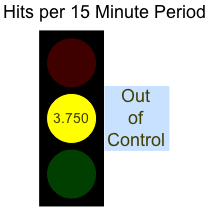

Stop Light

The Stop Light shows, at a glance, the status of a process being measured by displaying

Red when the current sample exceeds specified limits, Yellow if the process exhibits special-cause

variation, or Green when everything is in order.

|

|

|

Any numerical data can be displayed as a Stop Light. Specifying limits for the dataset is

required for the annunciation of the Red "out-of-spec" condition.

|

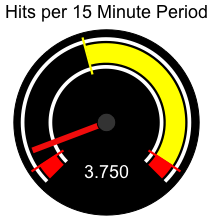

Gas Gauge

The Gas Gauge is a familiar form that displays the current sample value on an analog scale

with specified limits (red zone) and control limits (yellow zone) to help identify problems

with the underlying process.

|

|

|

Any numerical data can be displayed as a Gas Gauge. Specifying limits for the dataset is

required for displaying the Red "out-of-spec" zone.

|

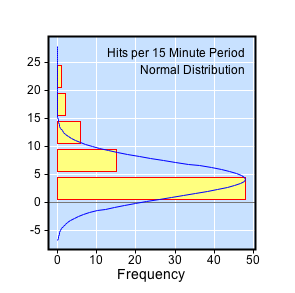

Histogram

The histogram shows how sample values are distributed in the dataset. As a reference, a normal

distribution line is drawn in blue, which enables quick determination of how the samples vary.

|

|

| Any numerical data can be displayed in this form. |

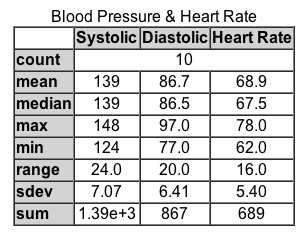

Basc Stats

The Basic Stats Chart presents a summary of statistics for the dataset organized by

column or observation. Each observation/column in the dataset is analyzed

and displayed as a column in the stats.

|

|

|

Any numerical data can be analyzed and displayed.

|

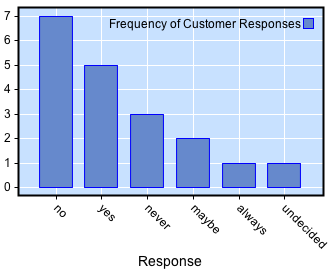

Pareto Chart

The Pareto Chart analyzes the frequency of occurance of values in the dataset. The

Values are sorted from most frequent to least frequent. An (others) bin is provided

to capture small remaining numbers of values.

|

|

|

Any textual or numerical data can be analyzed and displayed. Best used on discrete

sets of values like single words or short phrases. Numerical values may contain many

discrete values.

|

Control Charts

The following representations are "Control Charts."

These charts provide a quick graphical way to determine when unusual variation is

occurring in the sample data. Any sample falling outside of the Control limits is

colored red and indicates "Special Cause" variation.

Special-cause variation indicates that something significant has changed in the data,

either due to a change in process or the way it is measured.

See "Control Charts"on Wikipedia.

Other patterns in the data can also indicate special-cause variation. The "Western-Electric Rules"

capture how to identify these patterns.

See "Western-Electric Rules"on Wikipedia.

|

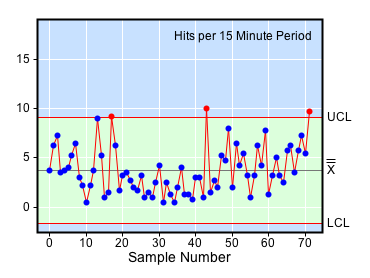

X-Bar Chart

The X-Bar Chart depicts the dataset as a sample sequence, with the addition of upper and lower

control-limit lines. Points falling outside of the control limits are a sign of special-cause

variation resulting from non-random sources.

|

|

|

Samples of up to 10 observations in a subgroup (10 columns) can be displayed. Each plotted

point represents the average of all the observations in the sample.

|

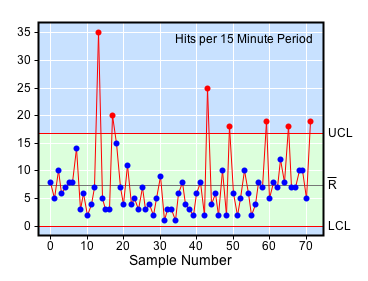

R Chart

The R Chart is a companion to the X-Bar Chart that indicates when special-cause variation

occurs within the observations that constitute a sample. These sample observations are

usually called a "subgroup."

|

|

|

Each plotted point represents the range of values in the sample subgroup. For samples

containing a single observation the difference between samples is used.

|

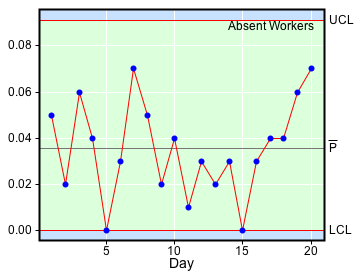

P Chart

The P Chart is a Control Chart used to analyze defects described by the number of

samples that represent failures, and the total number of samples. The fraction defective

is displayed.

|

|

|

The dataset being analyzed must have two columns defined: the first column must

contain the number of defects in the sample population, and the second must

contain the sample population.

|

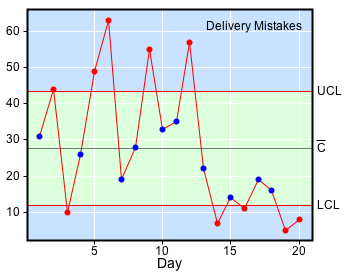

C Chart

The C Chart is used to analyze variation in count data.

|

|

|

Observations in each sample are summed and plotted with control limits. A constant sample

population is assumed.

|